For many years, it was the norm for factories to be “off-limits” to all concerned.

But are the citizens not related parties?

Children do not understand what is being made at factories in Higashiosaka.

There are so many factories with world-class technology so close at hand…

We need to open up the closed factories to the public.

Bring the joy of manufacturing together with the citizens.

Let’s remove the boundaries between residents, industry, commerce, schools, and government offices, and let’s play together!

It was with this in mind that “Let’s Go to Kooba! This is what started the “Let’s Go to Kooba!

We want Higashi-Osaka, the city of manufacturing, to continue to be a vibrant town.

This is one of the main objectives of our corporate activities.

KYOWA KOGYO CORPORATION / Seiko SCM CORPORATION / Settsu Kinzoku Kogyo Corporation / Fuse Kinzoku Kogyo Corporation / Matsushita Kosakusho Co.

In Higashi-Osaka, the “City of Manufacturing,” an open factory event “Let’s Go to Kooba!” was held in October 2018, co-hosted by Morimitsu SCM, Kinki University, and the City of Higashi-Osaka. In October 2018, Morimitsu SCM, Kinki University, and Higashi-Osaka City co-hosted the event, which was held at Morimitsu SCM.

In 2019, the event will be even more powerful! The two-day event will be held on September 21 (Sat.) and 22 (Sun.) at the Fuse Station North Exit Transportation Plaza, Fuse Station North Sanbangai Shopping Street, and Clare Hall Fuse. Higashi-Osaka is in the midst of the excitement of hosting the World Rugby Championships. Let’s go to Kouba! We hope that the “Let’s go to Kouba!” event will help people learn more about the manufacturing process and feel more familiar with factories. We hope that the “Let’s go to Kouba!” event will help people learn more about manufacturing sites and feel more familiar with factories. and a roundtable discussion was held by three people involved in the “Let’s Go to KOBA! and Professor Masakatsu Nishino of Kinki University discussed the significance of the event and their goals for the future.

(Interviewer: Shigemi Niki)

The Rugby World Championships was the catalyst for the event.

― What does it mean to hold the “Let’s Go to Kooba” project? Please tell us how it all started and how it came about.

Tatsumi: With the World Rugby Championships coming to Higashi-Osaka this year, we thought that Higashi-Osaka needed to do more to promote itself both domestically and internationally. However, it would be difficult for the City Hall to do this alone. So we asked Kinki University, a university in the city that has the ability to send out messages and has comprehensive capabilities, to do the job. The project started with the cooperation of eight professors from Kinki University, including Professor Nishino, the city of Higashi-Osaka, and the Chamber of Commerce and Industry, as a way of branding Higashi-Osaka as a “manufacturing town.

Mr. Yoshiyuki Tatsumi

Director, Higashi-Osaka City Monozukuri Support Office

Mr. Yoshiyuki Tatsumi has promoted public health and pollution countermeasures in the Health and Sanitation Department and the Environment Department at the Higashiosaka City Hall, and has been in his current position since 2018. Born in Higashiosaka City.

― How did Professor Nishino feel when you told him?

Prof. Nishino: We really started from scratch. We decided to see what we could do together with Higashi-Osaka City and Kinki University. We, in the Department of Cultural Design in the Faculty of Literature and Arts at Kinki University, have a variety of people, including professors of design, production, and sensibility studies. Professor Seifumi Okamoto, head of the Department of Cultural Design, initiated a variety of projects for comprehensive branding.

In the beginning, there was no such name as “Let’s go to Kooba! We didn’t even have a name for it. So, for the time being, we decided to visualize what kind of people are working in the factory and what they are doing inside the factory. We decided to “open these things up” to the local community, citizens, and other interested parties.

By “those things,” I mean how to communicate the inside of the factory to the outside world. In Higashiosaka City, factory tours are actually conducted, and there is also a project in which students on school excursions come to see the factory. Therefore, we decided to focus on “inner branding,” which was mentioned earlier by General Manager Tatsumi.

Mr. Yoshiyuki Tatsumi

Director, Higashi-Osaka City Monozukuri Support Office

Mr. Yoshiyuki Tatsumi has promoted public health and pollution countermeasures in the Health and Sanitation Department and the Environment Department at the Higashiosaka City Hall, and has been in his current position since 2018. Born in Higashiosaka City.

We want to make manufacturing more open!

― What prompted you to talk to President Kusaba?

General Manager Tatsumi: I have had a relationship with President Kusaba for some time. The thoughts of the top management of a company are very important for this kind of initiative. President Kusaba was very much inspired by open factories held in other prefectures. He also has a very strong desire for manufacturing and the desire to promote it. That is why we approached him.

Prof. Nishino: Some of the company’s business activities are confidential. So we asked, “Are there any companies that would be willing to open their factories to us?” We consulted with the Monozukuri Support Office.

I met with President Kusaba, who seemed willing to get involved, and I asked him to do so. It was in July of last year that the first collaboration between industry, government, and academia was established in this way.

Tatsumi: In this kind of project, it is not only the motivation of the candidate, but also the size of the company and how much it is willing to accept the candidate.

I think I put too much in. I packed so much in!

Mr. Yoshiyuki Tatsumi

Director, Higashi-Osaka City Monozukuri Support Office

Mr. Yoshiyuki Tatsumi has promoted public health and pollution countermeasures in the Health and Sanitation Department and the Environment Department at the Higashiosaka City Hall, and has been in his current position since 2018. Born in Higashiosaka City.

― Last year, the first “Let’s Go to Kooba! Did you get any feedback after the event?

Kusaba:The first thing we did was to invite citizens to the factory for the first time since the establishment of the company. We were skeptical about how we should welcome the citizens and whether they were really interested in manufacturing. We were skeptical about how to welcome the public and whether they would be interested in manufacturing, so we launched the project together with professors and students from Kinki University.

We included the keyword “rugby” in the event, with the Rugby World Cup in mind. We put down artificial grass outside and held a little rugby match. On the second floor, we held a workshop where visitors could experience metalworking and assembly. We also offered tours of the factory. We put in a lot of planning. We put in so much that it was like, “Is this too much? I put in so much that it was like, “Too much?

Prof. Nishino: First of all, there is no point in doing something if you don’t attract customers. We decided to try all the projects that came up. We have a lot of students and seminar students, so we brought them together for live performances. We had a guitar and singing group, an a cappella group, and so on. We did a lot of things throughout the entire building and on each floor so that visitors could enjoy a variety of activities.

Kusaba:Publicity activities were also very hard. Morimitsu SCM itself had no connections with the public. However, we were able to take advantage of the wisdom and information transmission capabilities of the City Hall. City Hall distributed leaflets to elementary and junior high school students in the neighborhood. What we couldn’t do, we got help from the people at the city hall.

We also formed a team of our employees for public relations activities, which we plan to do again this year. About two weeks prior to the event, we divided the team into six teams within bicycling distance from here, including the Kitatsumi and Fuse areas, and we went to each of the factories, shopping areas, restaurants, and other local residents to verbally inform them of the “Let’s go to Kooba! and handed out leaflets to local residents one by one. We wanted to convey the concept to the local people in their own words.

The response was so positive that on the day of the event, there was a line of people waiting to get in even before the event started. To attract people, we also focused on food and drink and held a marché in the parking lot. In addition to kebabs, crepes, and tapioca juice, we also had students from Kinki University set up a stall. We even invited a latte artist from Kyoto. All of that was sold out by about 2 pm. The meat from the round kebabs was so thin by midday that you could almost see the iron bars. That’s how many people we were able to attract. At first we thought we might be able to attract 300 people, but as it turned out, about 730 citizens and 100 presidents of local factories that we do not do business with came to the event. For a first attempt, the response was unexpectedly large.

Consider sending outward

Kusaba: I believe that Director Tatsumi and Professor Nishino have seen many events. Since this is the first time for me to attend such an event, I would like to ask you both, what is the difference between other events and “Let’s go to KOBA! is different from other events?

Prof. Nishino: I was appointed to Kinki University four years ago. My first involvement was with the “Monozukuri Support Office” of Higashiosaka City. Until then, I had been involved in art projects in the city, but as I got involved with Higashi-Osaka through the Monozukuri Support Office, I came to think that there was no need to pursue art here.

The characteristic of Higashi-Osaka is that “the contents of local communities, such as small and medium-sized enterprises and local factories, are alive. When I became involved with Higashiosaka City, I thought about how to communicate this to the outside world. As is true for other events, my thinking has changed to the point that “people do not gather because there is art, but because people gather, art is necessary.

Beyond the gathering of people, there is the revitalization of industry. To achieve this, we need to visualize what we have and welcome people. Many people come to Morimitsu SCM’s factory through events. Craftsmen who usually work alone and silently give demonstrations surrounded by many people. These extraordinary events are being held through the “Let’s go to Kouba! I think that through the “Let’s go to Kouba!” event, the employees of Morimitsu SCM were able to experience such an extraordinary event.

Tatsumi: Up until now, the industry-academia-government type of activities have involved product development and design that connected universities and companies. This time, industry-academia-government “joined forces” to create an event. This was the first time for us to use this kind of on-site initiative.

― What is the significance of industry-academia-government collaboration?

Prof. Nishino: I think this is a good experience for the students. They themselves have had the experience of participating in community activities such as neighborhood associations and children’s groups since childhood. But when they grow up, how will they treat children? Through the “Let’s go to Kooba! I believe that the experience of being involved in the community through “Let’s Go to Kooba!

I believe that the students directly understand what it means to “revitalize the community. By being involved in the event, students can experience what is often referred to these days as “social contribution” and “support activities. Companies are becoming more and more aware of these two issues, so when they graduate and go out into the world, it will surely be useful for them to know that they have been involved in, studied, and learned these things in the future. I am confident that they will be able to play a variety of roles in society based on the experience they acquired as students through these events.

This year’s “Let’s Go to Kooba! is even more powerful!

― What will this year’s “Let’s Go to Kooba! will be this year?

Kusaba: This year we will be holding an on-site open factory in the Fuse shopping district. Unlike last year, we will not be showing the entire factory, but we plan to rent out the Clare Hall in the Fuse Shopping Arcade and show a performance of craftsmanship on an hourly schedule. Using a projector, the demonstration will be like watching a movie. As soon as it starts, Clare Hall will instantly transform into a factory. We plan to invite three craftsmen of “welding,” “tataki sheet metal,” and “spatula drawing” to perform there for 15 to 20 minutes while shining a spotlight on them. A factory will appear in Clare Hall for two days only.

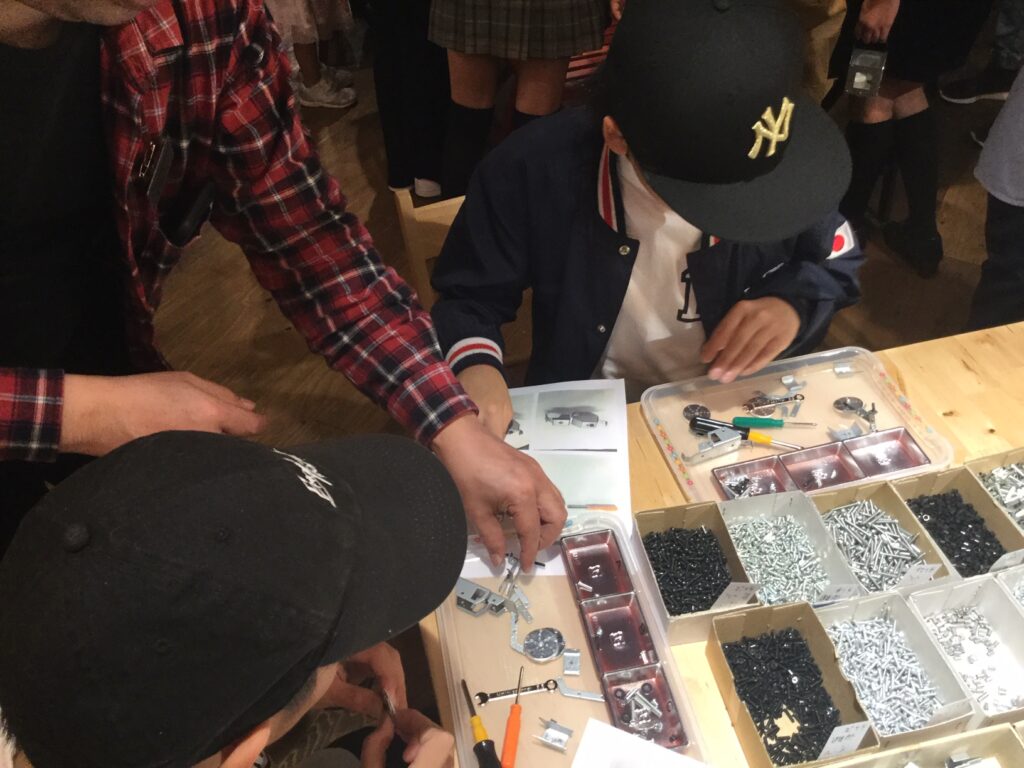

The rest of the day is a workshop to make with the craftsmen. This year, five factories will come together to create eight items. Craftsmen from the “wire mesh,” “tataki sheet metal,” “pipe fabrication,” “brushes and brushes,” and “metalworking” fields will team up with each other to create stationery items such as pen cases, stand boards, and blackboards. This is a workshop where we receive direct instruction from the craftspeople and create together. Last year we didn’t have time to think about it, but this year will be different in many ways.

General Manager Tatsumi: Higashi-Osaka City is hoping to devote itself to public relations activities this year as well. I think it was mentioned earlier that industry, government, and academia are all involved, and we would like to do this while taking advantage of our respective strengths. The main actor in these activities is the “industrial” companies. We will do our best in public relations and information dissemination using the tools at our disposal. We also plan to focus on introducing companies to each other.

Collaboration between students’ ideas and factory technology

Kusaba: The biggest difference between last year and this year is that the students and the factory created the event together. This year, we discussed and decided from the very beginning with 26 students from the Faculty of Literature and Arts at Kinki University what we would make and what kind of product planning we would like for the workshop.

― It is a collaboration of the students’ ideas of what they would like to have and the factory’s technology.

Kusaba: Yes, that’s right. The students also worked very hard on their own projects. It was really a great cooperation between industry, academia, and government. Now it is up to us to see how we can bring out the best in the actual event. I think the relationship between the students and the factory during the operation process was also very meaningful.

Prof. Nishino: This year, a total of 26 third- and fourth-year students from my seminar are participating. There are five companies in the workshop this time, and we are divided into groups of four students each to go to the factories and talk with the presidents of the factories. In addition, I will be uploading photos of, for example, “Let’s go to Kooba! and upload a photo of it to our Instagram!” We are also planning to incorporate activities that we think are good from our own point of view, such as “Upload photos of the “Let’s go to KOBA!

Kusaba: I am talking with the students about doing the same leaflet arrangement and PR activities that we did last year. Kusaba:We are discussing with the students about the leaflet distribution activity that we did last year. We are planning to visit all the stations along the Kintetsu line from Higashi-Hanazono to Fuse with the presidents of the factories. We have already assigned people to be in charge of each area.

― I understand that students will also participate in public relations activities this year.

Kusaba: Yes, the students are very motivated for public relations. Since they have participated from the very beginning, they communicate very well with the factory. Kinki University also shares the role as one company and takes care of the university campus, JR Nagase Station, and Kosaka Station. All that remains is the weather on the day of the event.

The Demon “Smile Curve”

― What is your vision for the future and the future of manufacturing in Higashiosaka City?

Kusaba: This year marks the 10th year since I became president. What I think from an objective view of factories in Higashiosaka, including my own factory, is that “even if the company has good technology, it is currently buried under the ground. It is not that the company has good technology, but that the technology of having good craftsmen in the company is not branded and not known to everyone. The company may be well-known in the industry, but I think it has not led to a place where craftspeople can be active.

Higashi-Osaka has a high concentration of factories for its area. However, the factories are not well coordinated with each other. Until now, the business flow has been in the form of first-tier subcontractors and second-tier subcontractors after the manufacturer. In the past, even if a company was not well known to the general public, if it was well known in the industry, work would come to it on its own from manufacturers who would sell it to the company. Now, however, that situation is on the verge of collapse. The era in which Japanese manufacturers do not have to be Japanese factories has been here for several decades.

Even if the factory itself does not become a manufacturer, it will become important to ask “how can we transmit our craftsmanship to the whole world? It is not enough to self-produce or to be able to make something difficult. It is not that a product sells because it is beautiful, but that it sells because people are moved by the story behind the product. I believe that “inner branding” of the craftsmen themselves will be necessary in the future. I believe that the ultimate goal is for craftspeople to develop the ability to obtain sales on their own, to be able to produce product planning, manufacturing, and sales in total, and to revitalize the overall economy.

― He said that it is difficult to shine a light on each and every craftsman.

Kusaba:Designers of products are featured, but there is no introduction that says, “It was made by XX Manufacturing. I think that the designers and the craftsmen who gave shape to the products are just as great as the designers. However, they have not been given the light of day. I would like to actively engage in activities to shine a light on them as well.

General Manager Tatsumi: This reminds me of the “Smile Curve. The “smile curve” is the shape of a graph showing the distribution of profits when a product is manufactured. The graph shows the part of the person who designed the product and the part of the person who sells the product, the two ends of which go up and look like a smile. As President Kusaba said, this part in the middle (the person who made the product) is not taken. It is not illuminated, and since no value is found in it, no profit is allocated to it. That is the current situation. The name “Smile Curve” is cute.

Kusaba:The graph itself is not cute at all. I would like to shine more light on the craftsmen and make the curve flatter.

Rugby World Championships and the three branding elements

― On a different note, the date of this year’s “Let’s Go to Kooba! coincides with the match date in Higashiosaka (September 22). How do you view the timing of the World Rugby Championships?

General Manager Tatsumi: There is no doubt that Higashi-Osaka City will attract attention from both inside and outside Japan. In conjunction with the Rugby World Championships, Higashi-Osaka City is also sending out a special message. Of course, “Let’s go to Kooba! information will also be disseminated, so I think it makes sense to hold this event at this time.

Kusaba: Higashi-Osaka is a “manufacturing town” and a “rugby town,” but it is also a “student town. There are four universities in the city. Therefore, Higashi-Osaka City has three branding elements: “manufacturing town,” “rugby town,” and “student town.

Professor Nishino: So far, we have worked with Kinki University, but in the future, if we can work with Osaka University of Commerce, Osaka Shoin Women’s University, and Higashi-Osaka University, it would be a good opportunity for students to learn more about the community. Starting this year, we have formed an executive committee for the “Let’s Go to Kooba! committee has been formed this year, and I hope we can involve other universities as well.

Tatsumi: In addition to the four universities, Higashi-Osaka City has concluded comprehensive agreements for collaboration and cooperation with Osaka Sangyo University (Daito City) and Osaka University of Economics and Law (Yao City), so we hope to involve the six surrounding universities as well.

Kusaba:It is true that factories tend to have a negative image: dirty, dangerous, low-paid, and often out of business. However, surprisingly, there are some factory boys and girls who think factories are cool. I hope that more and more young people will think that making things is cool. Because Higashi-Osaka is a town with factories close by, there are many opportunities for young children to come into contact with factories from the time they are small infants. I would like to take advantage of our proximity to factories and actively encourage people to think, “I want to be a craftsman in the future.

Manager Tatsumi: For example, when we ask high school students what they would like to do for work experience, many of them are in the commercial or welfare field. There are not many manufacturing sites. The reason for this is that they don’t have a clear image of what a manufacturing site is like. If people could understand that this is the kind of place they are looking for, perhaps there would be more requests for work experience.

Prof. Nishino: Many families of factory employees and their children are growing up without knowing what kind of work their fathers do or what kind of products they make. Last year’s “Let’s Go to Kooba! last year, it is a good opportunity for children to see their fathers at work, and it is also a good opportunity for children to experience manufacturing.

Click here for Rugby World Cup information (Rugby World Cup 2019 Osaka-Hanazono official website)

I want the lights your father made.

Kusaba: At our own brand exhibitions, when we have spatula craftsmen, who are the stars of our products, come to the venue and demonstrate the process of product creation, we get a huge crowd. In fact, I felt that the C of B to C, the final end user, was interested. When you get down to the manufacturer’s customers, they become citizens. What impresses people and makes them want the product? It is important for the people in the field to directly experience the joy of the citizens. The opportunity to connect citizens and factories through the event “Let’s go to Kouba! I felt that this is what the event “Let’s go to Kouba!

Last year, the most popular event was the “Let’s Go to Kooba! was a guided tour of the factory. Rugby, kids’ dancing, and other activities were all popular, but the guided tours, which were held once an hour, were attended by 40 to 50 people each time. We had so many people that I couldn’t see the back of the room.

In fact, it was the guided tours that I was most afraid that we wouldn’t get enough people. I thought, “I’ll have to make a cherry blossom.” I even thought. I really thought, “Who would be interested in a simple machine and work? But in fact, a lot of people came. I was very happy to be betrayed in a good way.

At first, I thought, “Civic events are for volunteers. But when we tried it, we learned a lot of things that you can never learn in your day job, and I think it was a very good experience for us. We realized that it was a great learning experience for us as well. Let’s go to Kooba!” allows employees to serve customers, craftsmen to call out to the public, and people to see what they are making. The factory side also gets to experience things that they normally wouldn’t be able to. People who have been silently making the same thing in the same place for decades are directly praised by those who see them.

One good thing happened last year. I received a call from the daughter of a craftsman who said, “I was so moved by the attention your father has been getting that I want a light (that he made). This person is married in Nagano, but we connected with her after watching “Let’s go to Kouba! and we connected with him. The craftsman is over 70 years old. His daughter had watched her father’s back as he made things since she was a child. When she saw her father’s work being shown to the general public for the first time, she was moved that so many people had seen and praised him.

General Manager Tatsumi: Recently, many craftsmen have been featured on TV and other media as having the “skills of a master craftsman,” but the actual “sound,” “smell,” “vibration,” and “power” are things you can never experience unless you are onsite.

― Does SEIKO SCM offer factory tours?

Kusaba: We actively accept factory tours. We also accept local elementary school students and, in response to a request from the Higashiosaka Tourist Association, we also offer guided factory tours on buses. I asked the elementary school students before their guided tour of the factory, and when I told them, “Your father or mother works in manufacturing,” their hands went up in a flurry. But when I ask, “What do they make?” they couldn’t answer. Even children don’t know what their parents make. That is how closed factories were. Japan is a “manufacturing powerhouse,” but the truth is that even people close to the factories did not know what they were making. In the past, it was commonplace for factories to have signs that said “No Entry Except by Authorized Persons.

General Manager Tatsumi: Due to noise and other problems, the entrances would be closed. So even from the outside, you couldn’t see what they were doing.

Prof. Nishino: For example, there is the keyword “Jutaku-Kogyo Kyosei. Jutaku Kyosei” means that industrial and residential areas should coexist well. For example, there is noise from factories every day. If local residents know that “this noise is coming from this machine,” they can deepen their understanding of each other, and the factory and residents can coexist well in the same area.

― Did you start accepting factory tours after you held “Let’s Go to Kooba! was it after you held the “Let’s Go to Kooba!

Kusaba: No, it started a little before that. It seems that there are many places that refuse factory tours. We once had an elementary school principal come to us, saying that he was turned down because his work would stop during busy times or for some other reason. When we took a walk through the town as part of a class at a nearby elementary school and asked the children, “Which factory were you most interested in? They said, “I want to visit the factory that makes plates. Apparently, they were talking about us. It wasn’t dishes at all, but there were a few kids in the class, so the teacher asked, “Would you be willing to take us on a field trip?” And that was the beginning of it. That was the beginning.

Let’s go to Koba! Expanding circle from

― What is the content of this year’s “Let’s Go to Kooba! What is the content of the “Let’s go to KOBA!

Kusaba: Largely “Craftsmanship Live Performance” and “Craftsmen in the Shopping Arcade. Let’s make stationery!” The workshop is called “Let’s make stationery! In the workshop, we make things together with craftsmen. The plates are made by pounding flat steel plates one by one. First, we start with a flat surface, then fold this, bend it, and make it into a tray. From there, we start designing. The marks made by the tapping are called “tsuchime,” and they give the dish a tasteful, handmade look.

― Did the factories participating in this project raise their hands voluntarily?

Kusaba: Yes, that’s right. Last year’s “Let’s go to KOBA! Many of the factories that came to the Actually, we don’t have business with the five companies that are in charge of the workshops. They came to us through the city hall, saying, “I saw your workshop at last year’s “Let’s go to Kouba! and some of them were introduced to us through the city office. It is like a group of presidents who had the idea in their hearts that they wanted to do something, too.

Prof. Nishino: The number of participating factories has increased from one last year to six this year. As we continue the program next year and the year after that, our goal is to have 20 or 30 companies in the future.

Kusaba: Events such as “Let’s go to Kooba! and other events are often thought to have nothing to do with our core business, but when I actually tried them, I realized that they have a lot to do with our core business. Through these events, I was able to learn what it means to be a manufacturer through actual experience. I learned a lot.

― Does this mean that the factory can experience something that it would not normally be able to experience?

Kusaba:Finally, the most important thing is that the person making the product can directly see how the end user is pleased with the product. I felt that direct contact between the maker and the buyer in the commercial distribution process is very meaningful in terms of understanding the actual site.

Prof. Nishino: Open factories like this are taking place in manufacturing towns all over Japan, such as Ota Ward in Tokyo and Tsubame-Sanjo in Niigata. They involve citizens and people from other prefectures to spread the word about what is being manufactured in the town’s factories. Based on such examples, Higashi-Osaka City has also been promoting the project, although we are a latecomer to the project.

On December 21 of this year, a symposium on open factories is planned at Kinki University. We plan to have representatives from “manufacturing towns” across Japan who are hosting open factories gather and present the effects and examples of open factories.

General Manager Tatsumi: This time, new “Let’s go to Kooba! are all young, in their 40s or so. It is very important that a network of such young presidents is being established, and we are very happy about it.

It is said that a horizontal network is very important for a manufacturing company like Higashi-Osaka, but at present, the network is mainly composed of presidents in their 70s or older who were engaged in manufacturing during the high-growth period. However, the current network is mainly made up of presidents in their 70s or older who were involved in manufacturing during the high-growth period. I think it is very important for Higashiosaka City to have a new network of young presidents through this kind of event for the future of the “manufacturing town”.

座談会記事 協力(順不同):東大阪市モノづくり支援室 / 近畿大学文芸学部文化デザイン学科 / 株式会社 源邑光 北野刃物製作所 / 共和鋼業 株式会社 / 株式会社 摂津金属工業所 / 布施金属工業 株式会社 / 株式会社 松下工作所

This year’s “Let’s go to Kooba! is an open factory on business!

In order to make “KOBA” more accessible to the public, it will be held at the Higashi-Osaka Industrial Fair as a traveling open factory, where you can experience craftsmanship live through live performances, make musical instruments on the spot and participate in live performances, and experience “making” stationery. We hope to see you there!

Date/Time/September 21, 2019 (Sat) 10:00-17:00, September 22, 2019 (Sun) 10:00-19:00

*Other event venues will have different hours, please check the website below for details.

[ Click here to visit the Higashi-Osaka Industrial Fair WEB site ].