Sheet Metal

- Home

- Sheet Metal

Sheet Metal

Proven track record in mass production in a wide range of fields.

We cooperate not only with our own factories but also with affiliated factories that possess superior processing technology, and we respond flexibly through smooth cooperation with trusted partner factories.We have experience in a wide range of fields, including sheet metal and stamped parts in all industries, such as lighting, hairdressing, and aviation.We are ready to handle the design of metal products as well.

Responds to mass production needs

Our sheet metal shop, equipped with a variety of processing equipment, enables us to respond quickly from planning to mass production, even for urgent prototypes and custom-made products. We accept requests for parts processing even from simple sketches. With our unique experience and technology, we can be consulted and entrusted even without a design drawing.

Complete machinery and equipment

- Sheet metal press processing

(Iron plates, stainless steel plates, aluminum plates, etc.) - lathe manufacturing

- Spatula, press, and various mold manufacturing

- Spatula drawing process

- Welding etc

Benefits for customers

Small lot (prototype/special order), no drawings OK

We have achieved small-lot production by owning various processing equipment.

In addition, since we have product designers on staff, we can also handle the production of custom-made parts and products based on simple sketch drawings.

Reflected in cospa & Taipa by stabilizing quality

By working on activities that do not introduce, produce, or produce defects, quality is stabilized and lead to shorter delivery times.

- Do not include defects -

We have established an acceptance inspection system at the time of purchase. - Do not make defects -

In order to suppress variations, jigs are used for processing. - Do not produce defects -

We carry out activities to ensure that shipping inspections are performed and that no defects are produced.

Maintaining quality and offering at a reasonable price

By making full use of our well-equipped in-house processing equipment and technology, we will reflect this in the cost of the ordering party.

In addition, it is possible to cooperate with reliable cooperating factories through a network unique to Higashi-Osaka, where various factories are concentrated.

Any way you can save time and money.

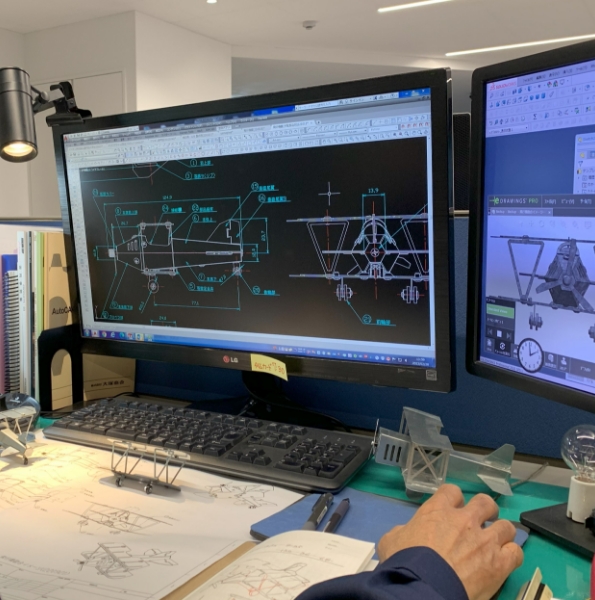

Leave the design to us! Product designer will respond

Our company, which has product designers, can provide not only parts but also sheet metal products.

We design using 3D-CAD, which allows us to shorten development time and stabilize quality.

If you want to place an order but the design is a bottleneck, please do not hesitate to contact us.

Machining/Welding

Morikou SCM’s technology and equipment come together

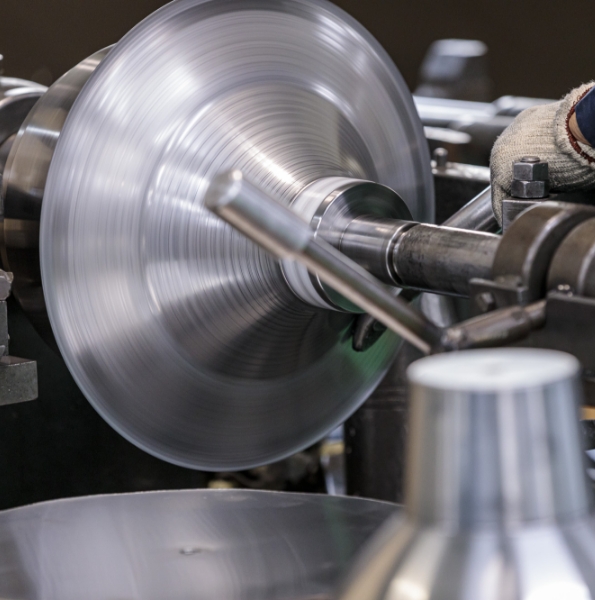

spatula squeeze

We use aluminum, iron, and stainless steel as materials, and handle spatula processing from 10mm to 1000mm in diameter with manual spinning and automatic spinning machines.

Spatula automatic machine

Spatula manual machine

Die/Lathe

Skilled craftsmen manufacture press dies, spatula drawing dies, processing jig dies, assembly jigs, etc.

In addition to orders for mold manufacturing, we also accept requests for sudden prototypes, simple mold manufacturing, and mold maintenance.

Press

We use stamping machines from 25t to 110t to manufacture post-processing of spatula-drawn parts, punching and bending of sheet metal parts, and press-drawn parts.

Sheet metal

By using sheet metal processing machines such as turret punch presses, shirring, roll processing, and brakes, initial costs can be reduced with manufacturing methods that do not require press dies, even in high-mix low-volume production.

We will propose the optimal manufacturing method for the number of lots and the shape of the product while also considering the cost.

Design

Part design using sheet metal is also available

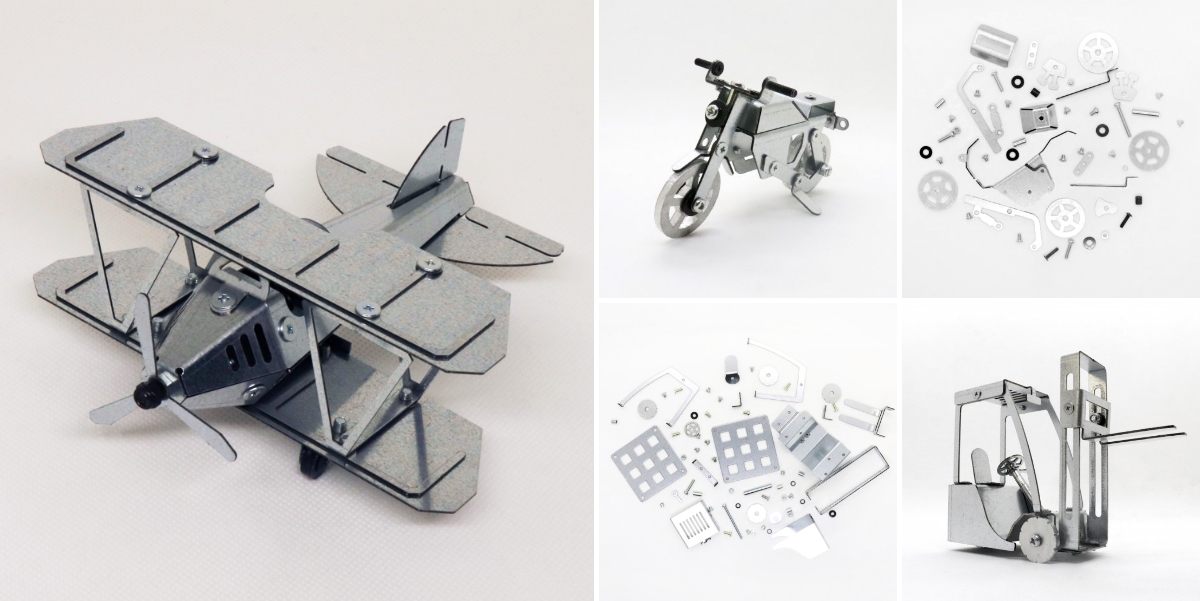

Please find your favorite sheet metal goods

Online shopEntire sheet metal factory

Equipment list

| Classification | Owned equipment | Maker | Model | Number |

| Computer | CADMAC | ー | ー | 1 |

| Press mold processing |

lathe | Tsuda | Hasshaku | 1 |

| Radial drilling machine | Yoshida | 2 | ||

| Sawing board | captain | 1 | ||

| NC milling machine | Shizuoka | AN-SRP | 2 | |

| plane grinder | Hitachi | GHL-B406 | 1 | |

| Spatula drawing | Automatic 1000 type spinning machine | japanese spindle | VF-T1000-NC-T6 | 1 |

| Hand drawing spatula processing machine | ー | ー | 1 | |

| welding process | spot welder | Amada | ID-40-ST | 1 |

| TIG Welding | Panasonic | YC-300BP4 | 1 | |

| Press working | Honing 25t | Nishimae Machinery | 1 | |

| Press machine 25t | Washino | 2 | ||

| press machine 35t | Nagao | NCP35 | 1 | |

| hydraulic press 25t | Koei Seisakusho | KPH-25M | 2 | |

| Hydraulic press 60t | Koei Seisakusho | KPH-60 | 1 | |

| power press 45t | Washino | 1 | ||

| power press 80t | Amada | 1 | ||

| Power press 110t | Amada | 1 | ||

| Sheet metal processing | unit punch press | Mazak | 1 | |

| servo turret punch press | Muratec | 1 | ||

| brake 600 | Toyo Koki | HYB-60 | 1 | |

| brake 1000 | Toyo Koki | HYB-306 | 1 | |

| Shirring 2000 | Toyo Koki | SA2390 | 1 | |

| Roll processing (R bending) | ー | ー | 1 |

SEIKO SCM’s ONLINE SHOP

Please find your favorite sheet metal goods.

Online Shop