Environmental testing

- Home

- Environmental testing

Quality Control/Environmental testing

We provide stable, fast, and high-quality products with a consistent quality control system.

We have a complete inspection environment for maintaining various processing processes and product quality in one building.

From planning and design to manufacturing and sales, with the coordination and cooperation of all product-related departments, we have a consistent quality control system that enables us to speedily produce high-quality products that meet performance and reliability standards through a stable production system. We provide it to our customers.

Benefits for customers

Short delivery times can be achieved by speeding up quality checks and troubleshooting.

By thoroughly implementing both quality design and quality control, we will reduce man-hours and strive to reduce delivery times and costs.

Quality design

Supporting product designers from the planning and design stage for the purpose of improving product quality

- Operation/Strength confirmation

- Waterproof measures and confirmation of waterproof performance

- Heat dissipation measures and evaluation of heat sinks, etc.

- Selection of materials such as die casting and resin

Quality management

The purpose is to maintain and improve product quality at the mass production stage.

- Parts acceptance quality inspection

- Product shipping inspection for mass-produced products

- Investigation of causes and improvement activities when problems occur

- Quality guidance to processing plants

- Providing and explaining data on quality and reliability to customers

Product evaluation agency OK! Please choose for me

With our environmental testing equipment and technology, we can not only inspect production and assembly processes, but also evaluate products on behalf of our customers.

If you have any concerns, please feel free to contact us.

In addition, when we perform product evaluation on behalf of our company, it will be a great advantage for the ordering party that the evaluation can be performed smoothly when the product is upgraded or when the specifications are changed.

Support for total cost reduction

By having various test equipment and facilities, it is possible to shorten the time from prototype to mass production.

It is also possible for us to collect evaluation data. This not only saves time but also costs, resulting in a total cost reduction.

Environmental testing

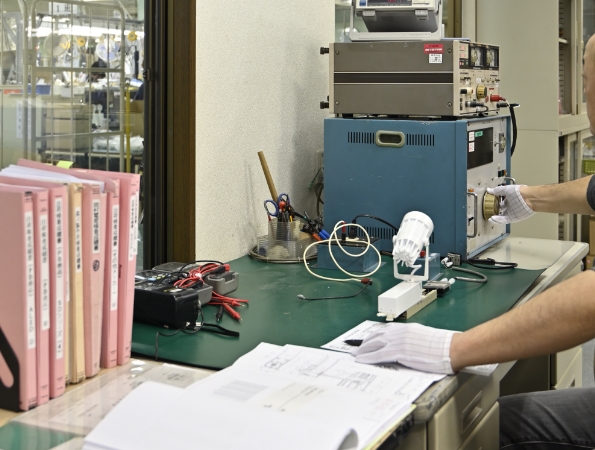

We conduct various tests to confirm that there are no problems with the products we design and manufacture.

Our company is equipped with temperature test equipment and high/low temperature test chambers, so we can verify the quality and performance of our products as many times as necessary, further improving the final product quality. can.

Temperature test

In LED lighting fixtures, the light emitted by LEDs does not generate heat, but the LED chips themselves become hot, so it is particularly important to design heat dissipation to reduce the temperature to a level where the performance of the product can be maintained. We pay particular attention to product safety as well as performance, and we measure the temperature of each part of the lighting equipment and strictly check whether it is within the standard temperature.

Main inspection items

- Will the rise in temperature of the product cause harm to the human body (burns, etc.)?

- Will smoke or ignition occur due to the rise in temperature of the product?

- Are the parts materials used in the product deformed, deteriorated, or shortened in life due to heat?

- Does the temperature of the electrical insulation material exceed the upper limit?

- Is the temperature of the parts that come into contact with construction materials and the mounting base free from the risk of fire?

A heat sink plays an important role in heat dissipation design.

Since the performance of a heat sink greatly affects the size and design of a product, we are also working on research into heat sink shapes that meet temperature standards and the selection of materials.

Constant temperature/humidity test

We conduct rigorous environmental tests from the prototyping stage and strictly confirm the weak points of products and parts before commercialization.

Complete machinery and equipment

- Thermal shock test: Performance inspection under rapid temperature change from low temperature to high temperature

- Low temperature → normal temperature → high temperature cycle test: Performance test that repeatedly gives environmental changes of low temperature and high temperature

- High temperature and high humidity → room temperature cycle test: Performance test that repeatedly gives high temperature and high humidity environmental changes

- Operation test and characteristics inspection of products at low temperatures (possible down to -40°C) (development of equipment for freezers, etc.)

- Quality evaluation such as heat resistance temperature, life estimation, strength, etc. of new materials and new structures

- Moisture-proof testing of products (such as development of bathroom fixtures)

- Moisture resistance test of insulating materials (material evaluation), etc.

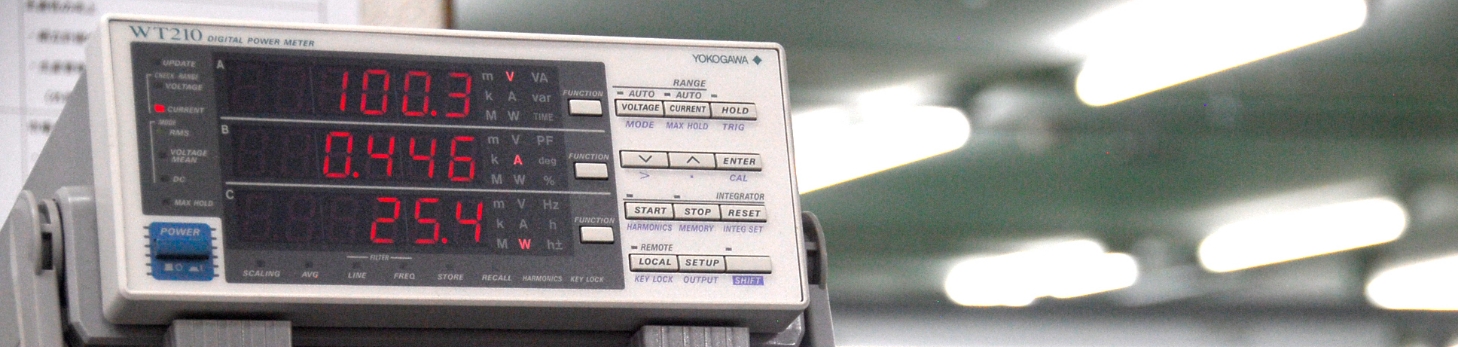

Aging test

In order to detect initial defects in products before shipment, we have prepared an aging check environment. Aging is performed under various conditions, and accidental defects such as electronic components and soldering work are discovered at an early stage through actual operation tests.

We also carry out long-term aging to accelerate deterioration, and conduct durability evaluations to determine whether there will be any problems with the life of the product.

Of course, if there is a request from the customer, we also respond to requests for <environmental tests only> (temperature, constant temperature and humidity, aging).

Please feel free to contact us.

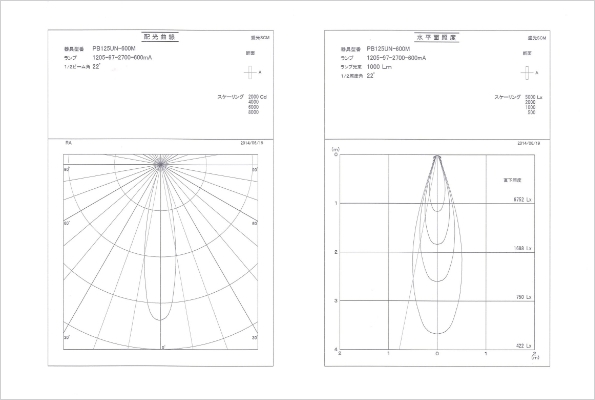

Light distribution test

Light distribution data indicates in what direction and with what intensity the light emitted from a lighting fixture is emitted. These are the basic characteristics of lighting fixtures and serve as basic data for lighting calculations.

We can measure data necessary for space lighting planning, such as fixture efficiency, upper luminous flux, lower luminous flux, lighting rate, fixture spacing, horizontal illuminance, and vertical illuminance.

Of course, if there is a request from the customer, we can also respond to requests for <light distribution test only>. Please feel free to contact us.